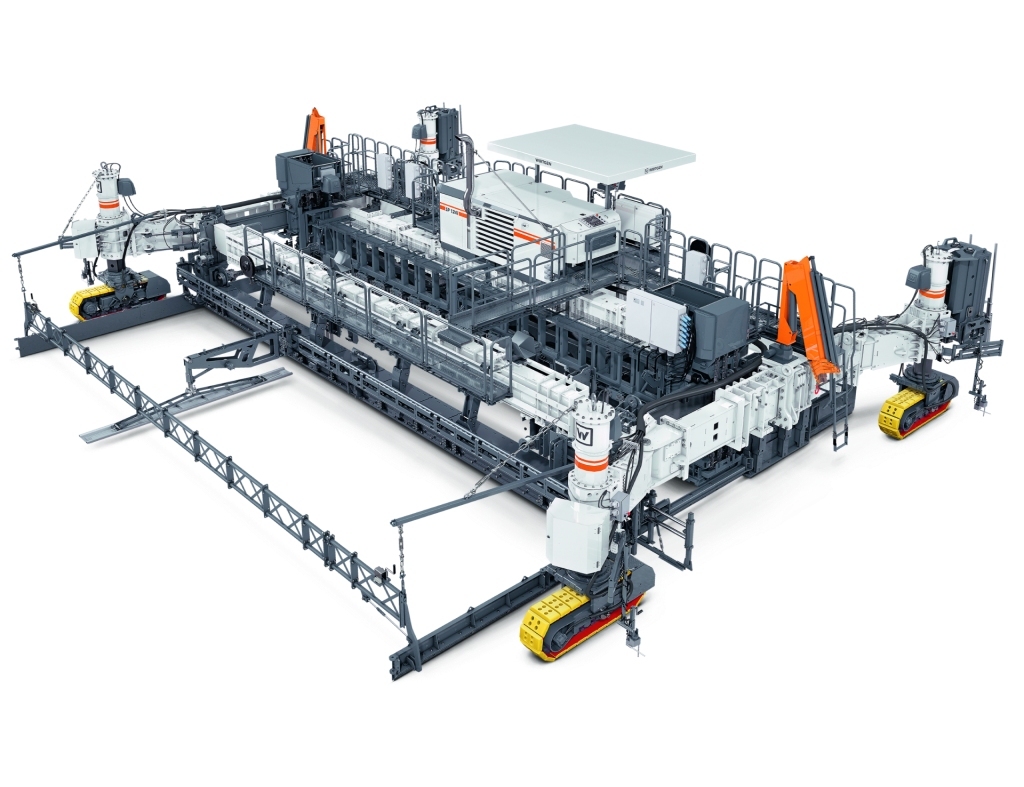

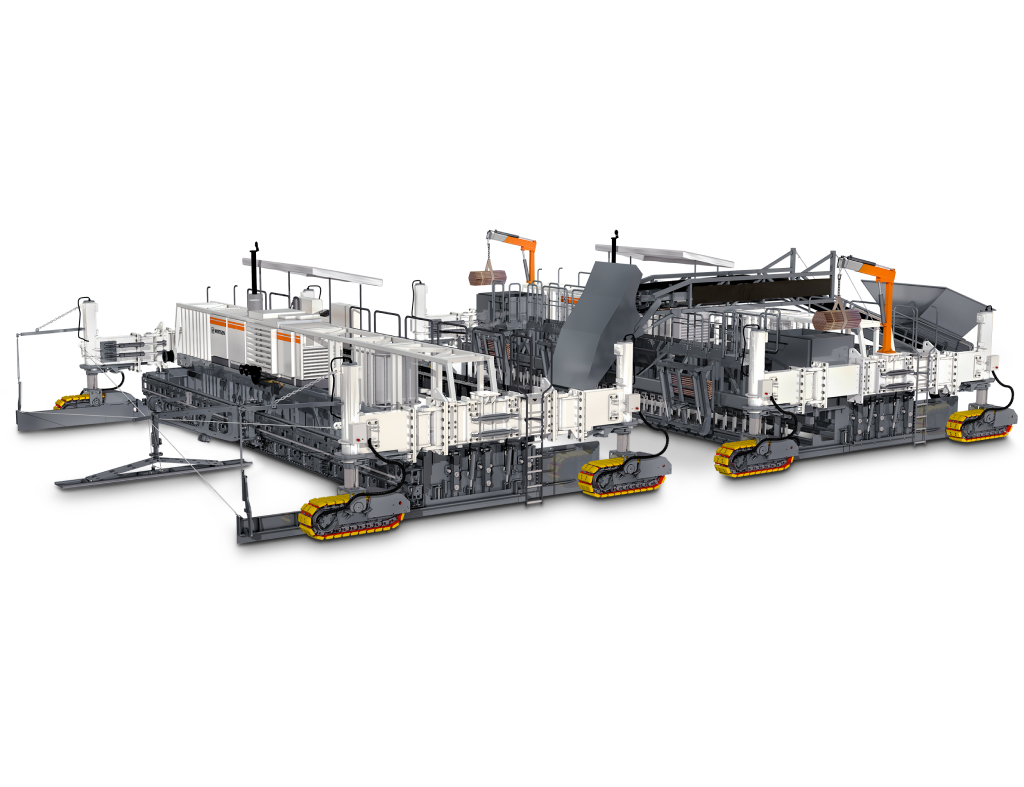

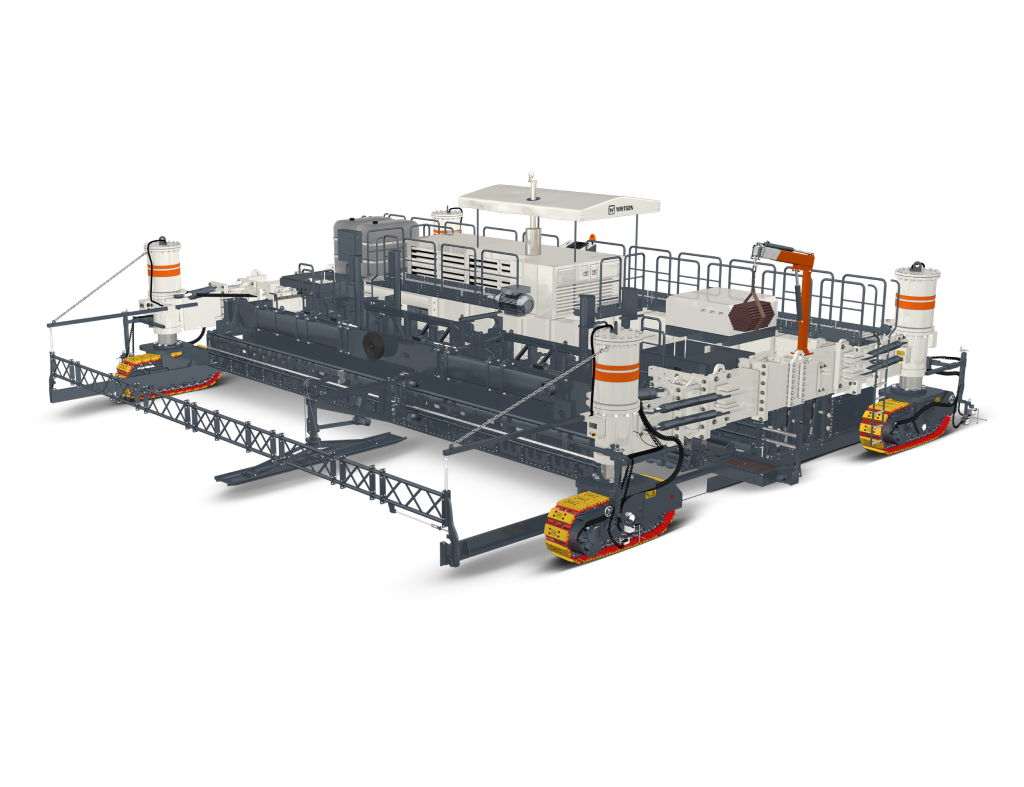

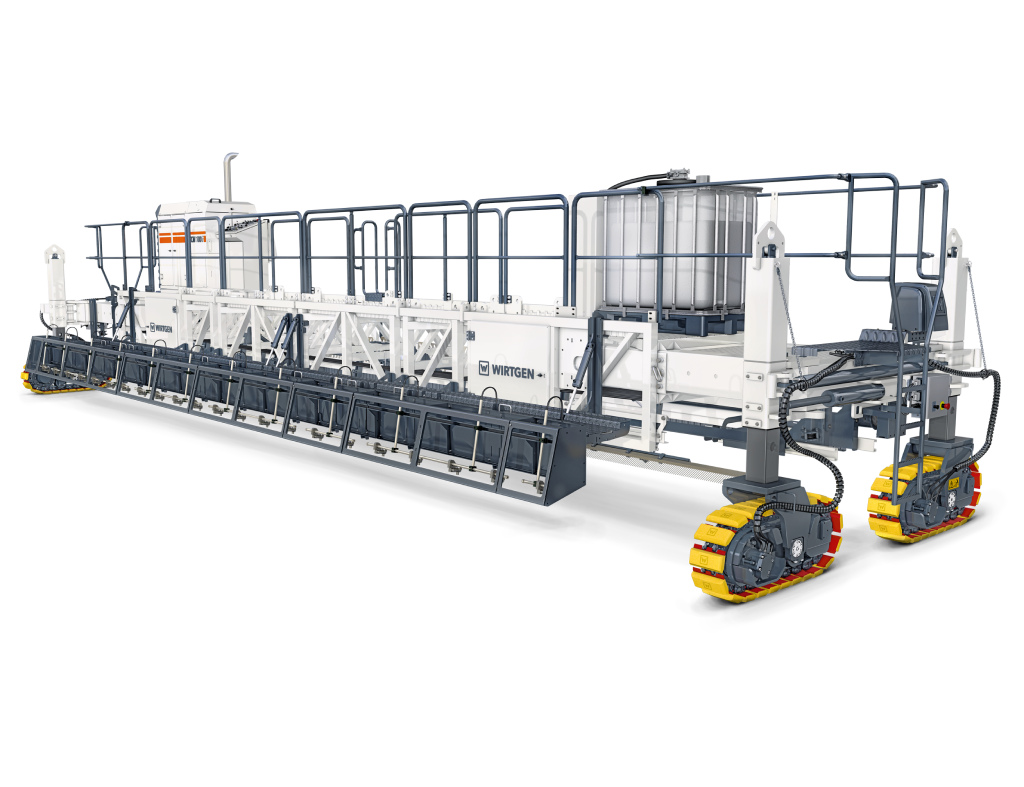

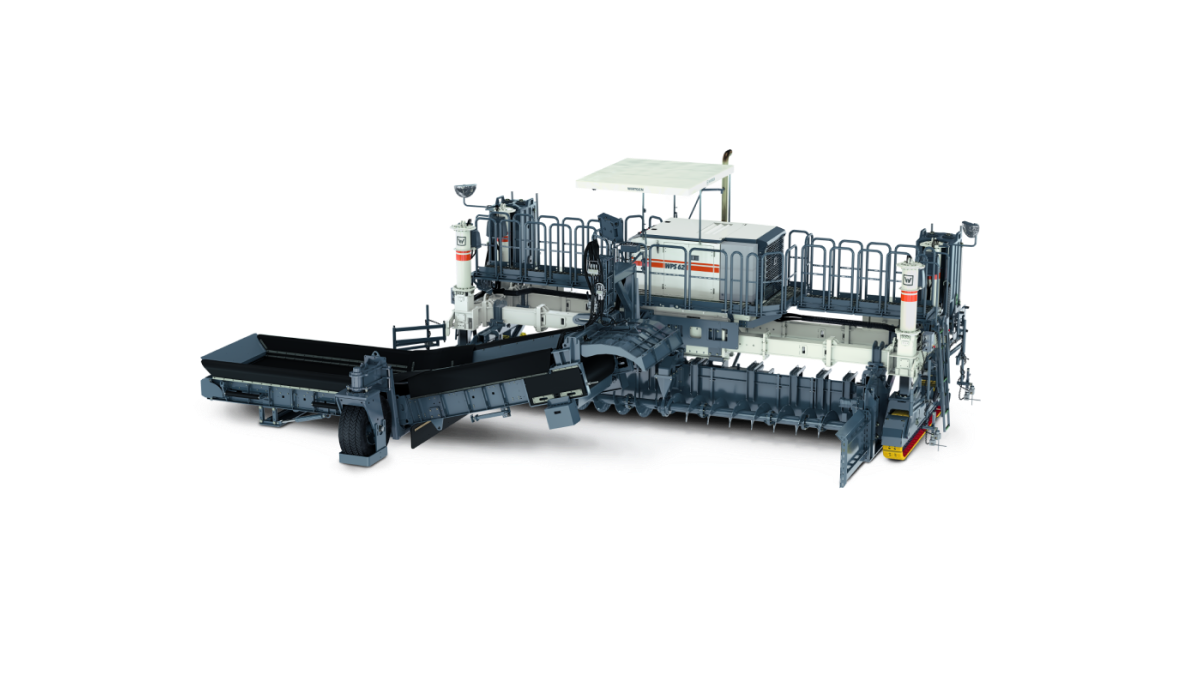

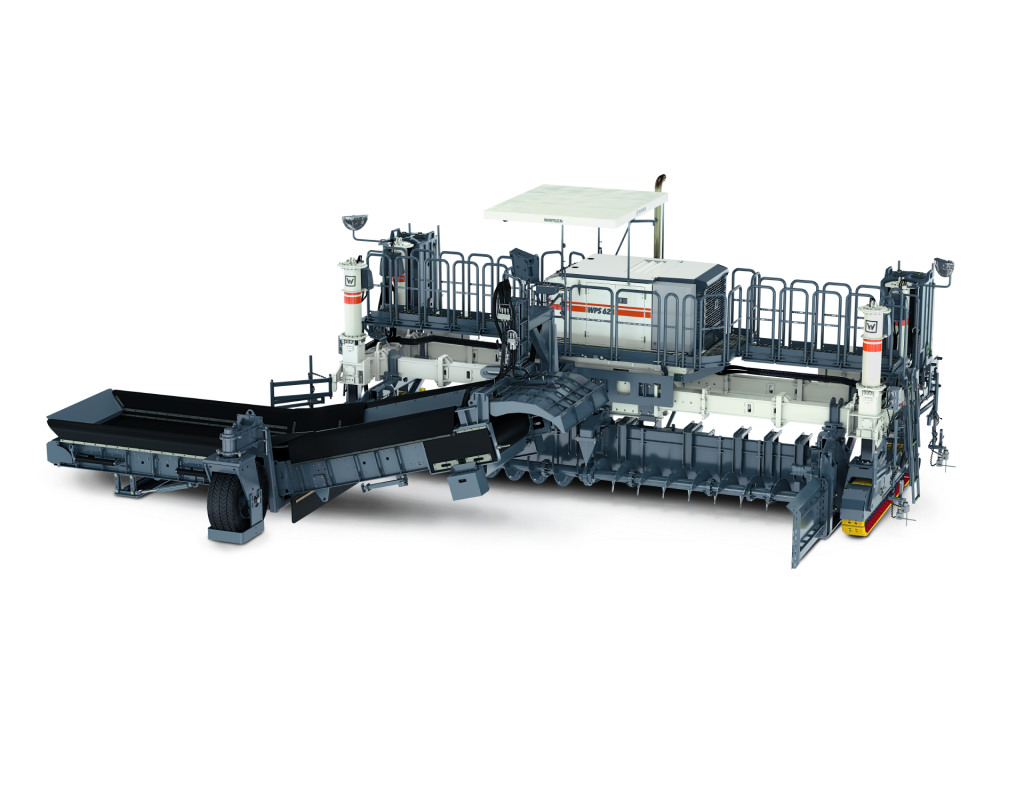

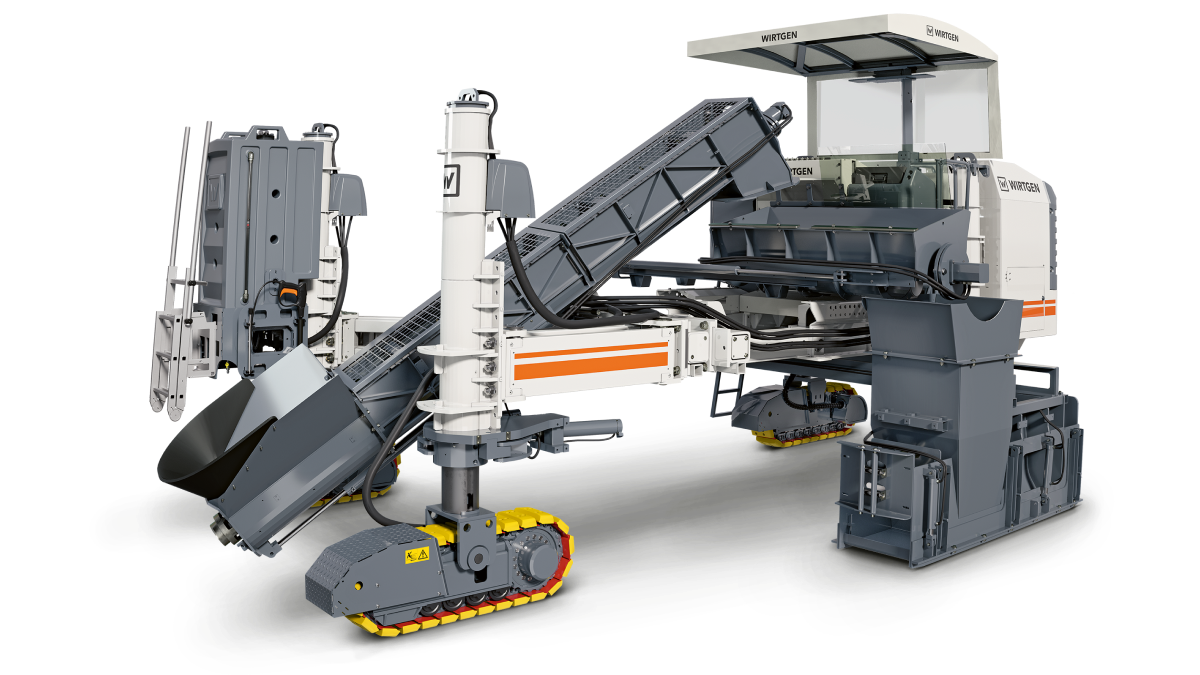

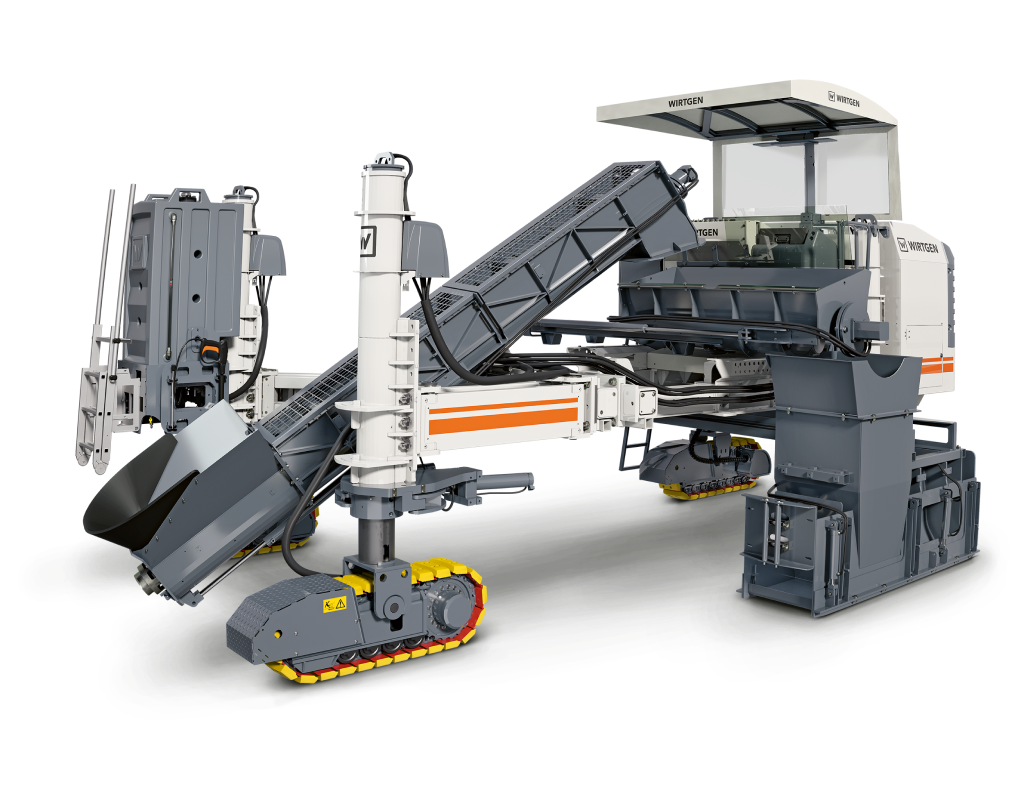

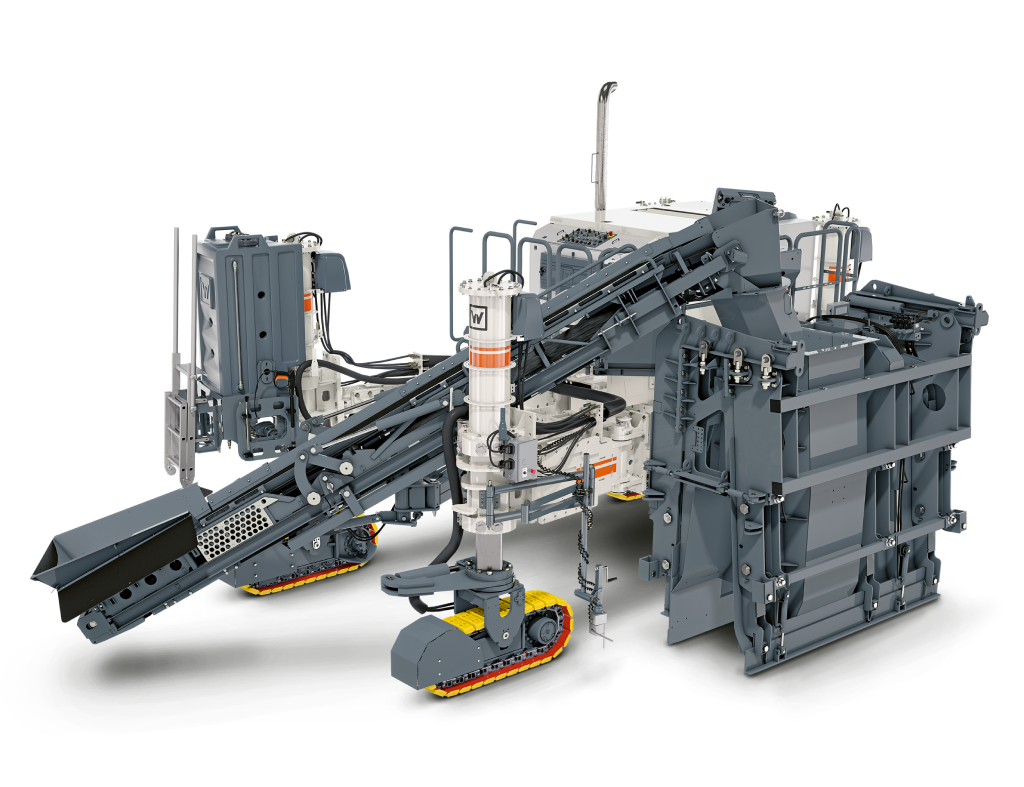

Offset Slipform Pavers

With offset slipform pavers, the concrete is transported into the offset mold via a loading conveyor or a conveyor auger. The offset mold can be mounted on the left or right-hand side of the machine. A number of molds in a wide range of different shapes and sizes are available for individual applications. The offset profiles are continually produced monolithically, with or without reinforcements. Machine features include a top-quality machine control system, a practical steering and drive system and stringline-free concrete paving.

Brochures

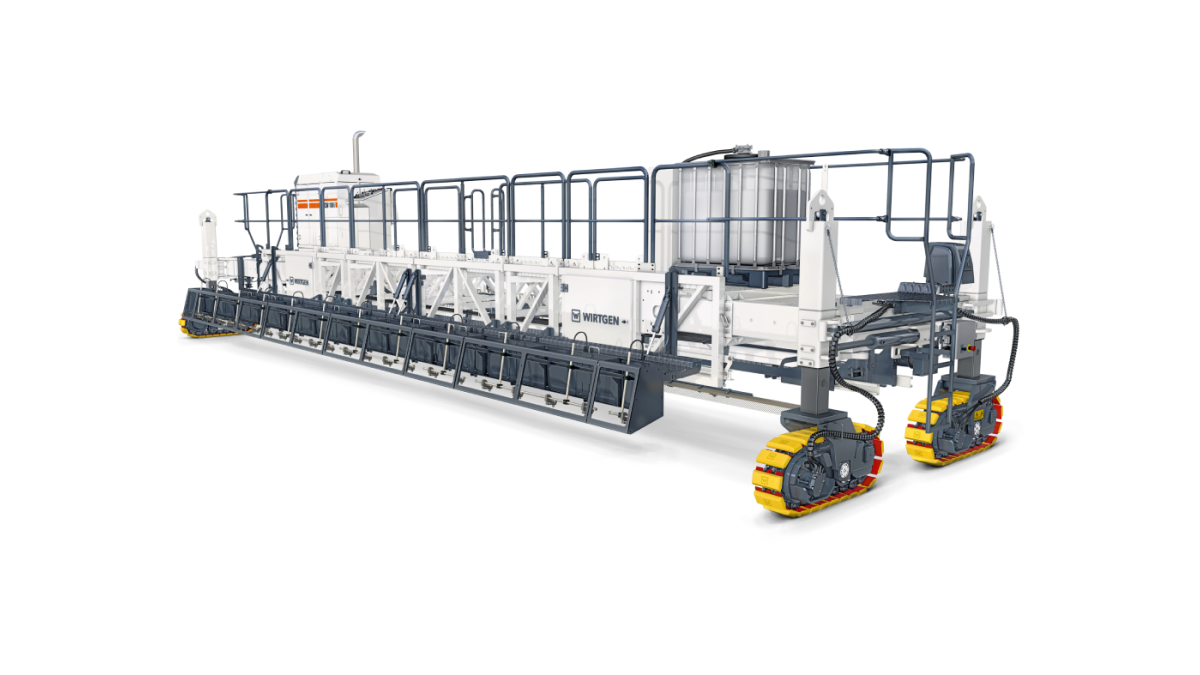

SP 15

Max. mould width

1,800 mm

Max. mould height

1,300 mm

Rated power

92 kW / 125 HP

Ow, CE

4,495 - 4,745 kg

SP 25

Max. mould width

2,500 mm

Max. mould height

2,000 mm

Rated power

118 kW / 160 HP

Ow, CE

13,600 kg

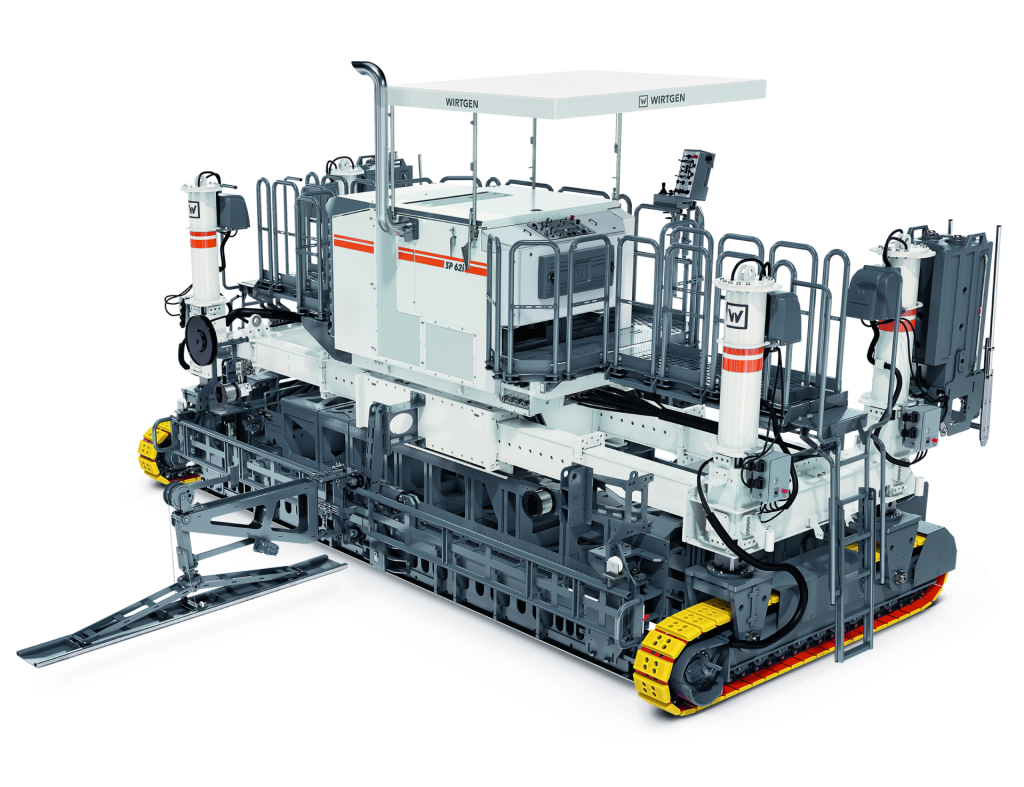

SP 61

Max. mould width

4,000 mm

Max. mould height

3,000 mm

Rated power

155 kW / 211 HP

Ow, CE

17,400 kg